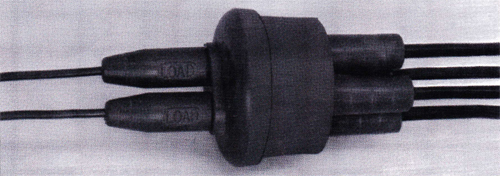

Installing SEC Double Pin Connector Kit

| 1. |

Select segment size, a minimum of 5/64” smaller than outside dimensions of insulation on conductors. Cut segment to be used at cutting ring with sharp knife. (see illustration for cutting ring dimensions.) |

| 2. |

Apply silicone lubricant (Provided in kit) on conductor and segment opening. Conductors must be clean and free of foreign materials. . |

| 3. |

Insert conductors through opening of segments approximately six inches beyond end of splice box body and pin body. |

| 4. |

Trim insulation from conductors the length of lugs and attach to lug assemblies, tighten lug assembly according to inch pound chart. |

SEC Double Pin Connector Kit

| 5. |

Apply silicone lubricant to inside of segment (splice box body) around conductors. |

| 6. |

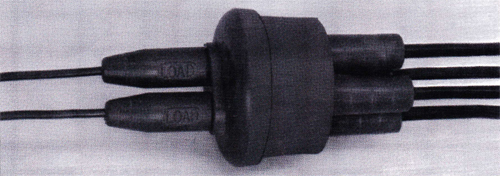

Push cap lug assembly and conductors into splice box body and check for proper seating. Cap and body must be clean and free of foreign material for proper seal. Lubricate splice box cap seal ring and inside seal ring splice box. |

| 7. |

Push pin and conductor back into connector body. |

| 8. |

Plug in connector body into cap of splice box cap. Apply silicone lubricant to pin connector to eliminate rubber friction. |

| 9. |

It is recommended that conductors be taped or tie wrapped from four to six inches from base of splice box. Although not required, electrical tape can be place around outside rim of splice box body for double protection. SEC connector kits will provide a waterproof connection that can be disconnected and reused. |

SEC Double Pin Connector Kit