Installing SEC Connector Splice Box

| 1. |

Select segment size a minimum of 5/64” smaller than outside dimensions of insulation on conductors. Cut segment or segments to be used at cutting ring with sharp knife. |

| 2. |

Apply silicone lubricant (provided by kit) on conductor and segment opening. Conductors must be clean and free of foreign materials. |

| 3. |

Insert conductors through opening of segment approximately six inches beyond end of body of splice box. |

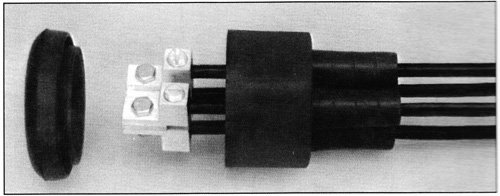

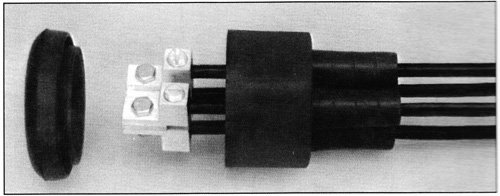

| 4. |

Trim insulation from conductor the length of lugs and attach to lug assembly, tighten lug assembly according to inch pounds chart. |

Installing the Splice Box

| 5. |

Apply Silicon lubricant to inside of segment (splice box body) around conductors. |

| 6. |

Push lug assembly and conductors into body of splice box. |

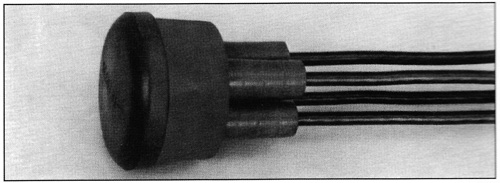

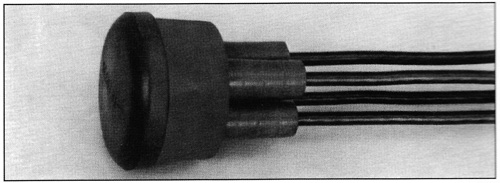

| 7. |

Snap into splice box body. Cap and body must be clean and free of foreign materials for proper seal. Lubricate splice box cap seal ring of splice box. |

| 8. |

It is recommended that conductors be taped or tie wrapped from four to six inches from base of splice box. Although not required, electrical tape. |

Installing the Splice Box